Flint Systems delivers a 100% pass rate for tower crane practical exams with HTC VIVE

Discover how Flint Systems makes heavy machinery training safe, efficient, and successful with digital twin simulation using VIVE.

Articles | AEC | Use Case | Training/Simulation

5 minutes read

Training operators of tower cranes, warehouse forklifts, excavators, and other specialized machinery has traditionally been a tricky challenge. By necessity, construction firms must perform such training in industrial sites alongside ongoing operations, which isn't ideal, given that inexperienced operators can pose a severe risk to the equipment they're learning, any surrounding cargo, and on-site personnel.

Flint Systems addresses this problem – and many more – with simulator technology and virtual reality training powered by HTC VIVE. Trainees using Flint Systems technology simply wear a VIVE headset and sit at a replica version of the control system they'd use to operate the real-life machinery. From there, they can learn how to operate massive machines, even under adverse weather or in dangerous conditions, with absolutely zero threat to ongoing operations. The trainee can even discover if they're frightened of heights!

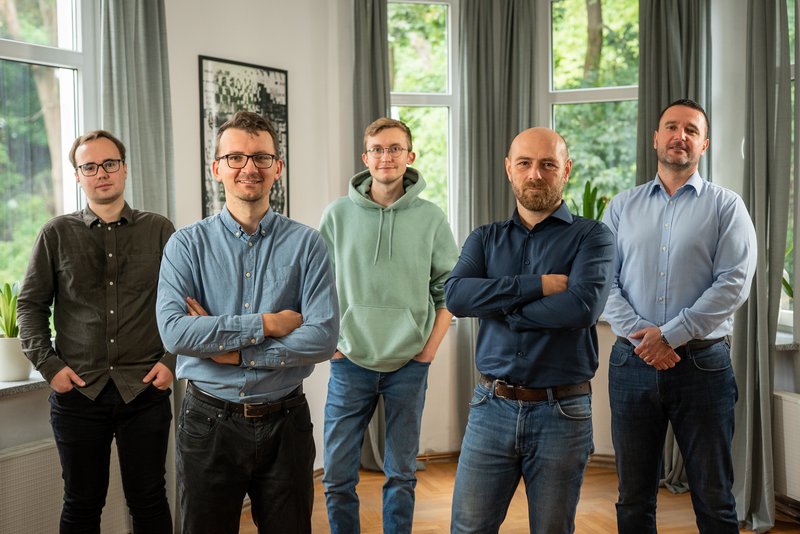

"Generally, training of specialized machinery operators is dangerous, expensive, and tough to organize. Therefore, we make it easy with complete virtual reality simulators," says Leszek Tarnawski, President of the Board at Flint Systems.

"It doesn't matter what industry you come from. Whether you work in construction, offshore, in ports, freight and logistics, or in the maritime industry – our VR training simulators solve the problems inherent in training heavy machinery operators. We provide an innovative, cutting-edge solution, linking the best software and hardware (delivered by companies like HTC VIVE) to provide a fully immersive platform that will help upgrade the training of employees in an effective, safe, and engaging way."

Increasing safety, reducing cost

One of Flint System’s most recently delivered projects was a tower crane simulator for the Polish construction company Maukran.

Flint Systems built a corresponding digital twin of the Maukran tower crane controls inside a digital environment. The crane's virtual control systems are connected just as the connections in the actual machine. Additionally, all digital parts are built according to the machine's physical parameters and specifications, including masses, density, stiffness, and endurance limits, meaning the digital crane can become damaged under the same irregular forces as its real-life counterpart.

"Our team cooperated closely with Maukran and the equipment manufacturers to replicate the equipment 1:1," says Leszek. "Our qualified architects, engineers, developers, and designers can make any kind of software and hardware in this manner."

When a Maukran employee needs to learn tower crane operation, they wear a VIVE Pro 2 headset with a resolution over 2K for each eye. The tower crane's control devices have equivalents mapped in virtual reality, and the simulator also tracks and displays the simulation participant's gestures and hand positions. Haptic feedback technology creates a sense of what it feels like to use the actual device.

When a Maukran employee needs to learn tower crane operation, they wear a VIVE Pro 2 headset with a resolution over 2K for each eye. The tower crane's control devices have equivalents mapped in virtual reality, and the simulator also tracks and displays the simulation participant's gestures and hand positions. Haptic feedback technology creates a sense of what it feels like to use the actual device.

When the trainee is ready to go, it's a simple case of learning the controls and controlling the crane in VR without worrying about causing any accidental injuries.

"We solved many problems with this tower crane simulator," says Leszek. "Firstly, we increased the safety of training. Previously, Maukran used machinery running on a construction site, which is far from ideal. In virtual reality, this isn't a concern. What's more, we can also replicate dangerous and even life-threatening events, such as what to do when an operator drops a load, a rope snaps, or harsh weather conditions. Such scenarios are impossible to train for in real life without causing damage or death.

"We solved many problems with this tower crane simulator," says Leszek. "Firstly, we increased the safety of training. Previously, Maukran used machinery running on a construction site, which is far from ideal. In virtual reality, this isn't a concern. What's more, we can also replicate dangerous and even life-threatening events, such as what to do when an operator drops a load, a rope snaps, or harsh weather conditions. Such scenarios are impossible to train for in real life without causing damage or death.

Flint Systems’ simulation technology also posed significant cost savings. "Thanks to this simulator, Maukran didn't need to rent any industrial vehicles for training, and unlike a real crane, the virtual crane is available 24/7 in any type of lighting conditions. Also, the virtual tower crane uses much less energy than running a real one!

Flint Systems’ simulation technology also posed significant cost savings. "Thanks to this simulator, Maukran didn't need to rent any industrial vehicles for training, and unlike a real crane, the virtual crane is available 24/7 in any type of lighting conditions. Also, the virtual tower crane uses much less energy than running a real one!

"Overall, the virtual reality training is extremely efficient for Maukran; it solves many practical problems while also delivering effective training thanks to its immersive nature."

"Overall, the virtual reality training is extremely efficient for Maukran; it solves many practical problems while also delivering effective training thanks to its immersive nature."

Best-in-class VR

Flint Systems uses Unity to create its software and Motion Systems for the real-life motion platforms involved with some simulations. For the virtual reality headset itself, VIVE was the easy choice.

"Our product forces us to use the best virtual reality goggles available. That's why we chose HTC VIVE," says Leszek Tarnawski, President of the Board at Flint Systems.

Leszek adds that the resolution offered by VIVE headsets was critical for such simulations. "Resolution was essential for us in headset choice," he says. "Thanks to the high fidelity in the VIVE Pro 2, a trainee can easily see the complex details of a construction site while sitting and controlling the crane. This effect of realism is simply hard to achieve with lower resolution headsets."

Leszek adds that the resolution offered by VIVE headsets was critical for such simulations. "Resolution was essential for us in headset choice," he says. "Thanks to the high fidelity in the VIVE Pro 2, a trainee can easily see the complex details of a construction site while sitting and controlling the crane. This effect of realism is simply hard to achieve with lower resolution headsets."

It's not just the technology itself that's impressed Flint Systems, they also wanted a technology partner that cared about more than just the business transaction, and it found one in HTC.

"We have a great business relationship with HTC VIVE," says Leszek. "We're not treated like clients but as part of a wider 'meta' community. We exchange information with the VIVE team, seek common business opportunities, and participate in events together. It feels like a real partnership, and that's very important to us."

Producing great results

Results on the tower crane simulator have been more than satisfying for both Flint Systems and Maukran. A special analytical module enables machinery trainers to check trainees' performance, and the results prove the simulator’s efficacy: "The practical exam pass rate is 100% - there has never been a case of a trainee failing a public exam after training in VR (as of June 2022)," says Leszek.

The tower crane simulator is just one of many projects recently delivered by Flint Systems. The company also recently released a forklift training simulator for the Polish governmental Office of Technical Inspection (UDT), and many similar projects are in the pipeline. Whatever's coming next for Flint Systems, virtual reality will play a key part in keeping the company in pole position.

"Other companies are offering VR training simulators, but they are not as advanced as those produced by Flint Systems," says Leszek. "With HTC VIVE on our side, we offer a level of immersive engagement you can't get elsewhere. We're glad to say we're leaders in the field."

If you’re interested in learning more about vertical-specific solutions and how they can help impact your business—send your contact info to one of our Enterprise Account Executives.

Contact Sales